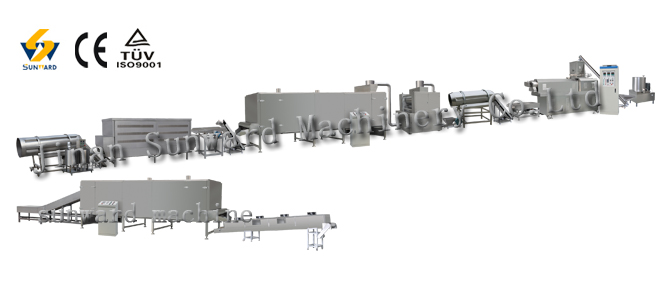

The flow chart forcorn flake production line:

1) Raw material: The raw material for corn flake is very important,as it will directly affect the quality of the corn flake which are produced by our equipment. In other hand, the quantity and scale of other nutrition material is also very important.

2.) The extrusion and shaper: The core part for producing high quality corn flake is the extrudering and shaping . In order to produce thick crispy goodcorn flake, the corn flour must be totally matured, but couldnot be puffed in corn flake producing.

3) Cutting: To cut the material which have been extrusion and matured by twin screw extruder to be same size pellet shape products. The products will be in semitransparent type.

4)Pre-drying: The products after extruder will be sent to the dryer for pre-drying, after drying, the material will be tension after be dried on the surface,so they will be not stick together. This is good for pressing by the press machine.

5) Presser: Presser technology is also the core part for the corn flake producing,so it have high quality request for the pressing machine. The surface of the presser roller must be very smooth,and the roller must be keeping constant temperature.

6)High temperature roasted: This is important process for producing high thick and crispy corn flake.

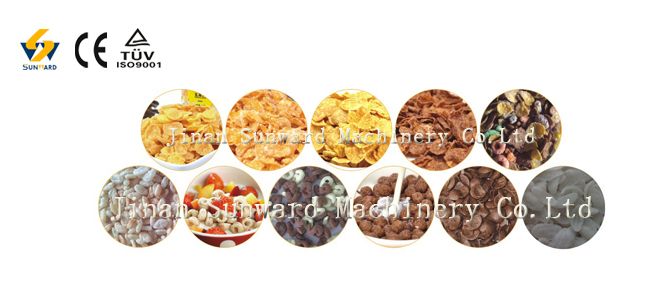

7)The corn flake after be roasted, then will be cooling by the cooling machine. Then people could get the corn flake product. According to market demand, a lot of corn flakes will be deeply produced which are like sugar coating,salt fryig or chocolate coating and so on.

Copyright © Jinan Sunward Machinery Co., Ltd. 2014 All rights reserved

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com  E-mail:gnsales@cnsunward.com

E-mail:gnsales@cnsunward.com

①Factory Address --Xiaoluzhuang Industrial Park, Jinan City, China

②Room 1304,Shanxin Mansion,Qizhou Road,Huaiyin District,Jinan city,Shandong Province,China