First, determine the choice of a single or

twin screw extruder screw extruder according expanded material from the structure and purpose, in general:

Single-screw extruder: suitable for the treatment of various raw materials and general livestock feed.

Twin-screw extruder: shaping the

final product requirements and pretty good appearance, and the density

of uniform ripening degree adjustable feed (aquatic feed, pet food) as

well as high value-added raw materials (starch, tissue protein) and so

on. It should be noted that the above division is not absolute, for

example, we recommend using a twin-screw production of aquatic feed, but

there are many companies with a single screw aquatic feed production.

There are many differences in this article describes both for

aquaculture feed production, in short single-screw and twin screw,

compared with the following advantages:

High production rate, up to 98% or higher

Particles forming a good, uniform grain shape. Twin-screw clamping pressure is stable, to ensure consistent particle formation.

Strong unique twin-screw pumping capacity, to ensure that no anti-spray,

clogging. After emphasizing quality, materials containing a high amount

of steam, a single screw in the feed zone prone to overflow steam,

anti-spray, resulting in a stream instability blocking machine, and a

twin-screw similar situation does not occur.

Continuous and stable production of a variety of small particles

products. In the production and below 2mm diameter of the particles, the

single screw unstable conditions, the production rate will dip,

material type will deteriorate.

Density control is more stable and reliable. Material in the twin screw

extruder barrel more fully melted, evenly, you can precisely control the

production of floating material, submerged materials and products

slowly sinking.

Recipe for wide adaptability, can adapt to high-energy production

formula. Twin screw can produce 11 to 13% fat content (up to 17% of

foreign materials known) of the high-energy formulation, while the

single screw generally not more than 6 to 8%.

Easy operation, stable production process.

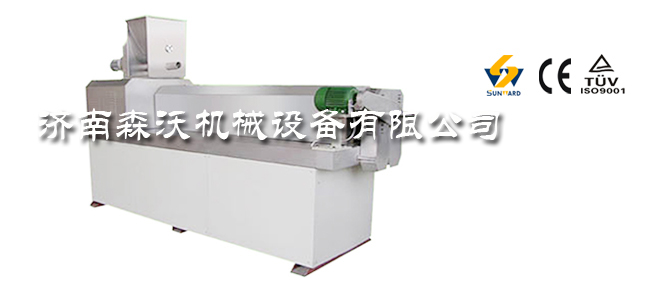

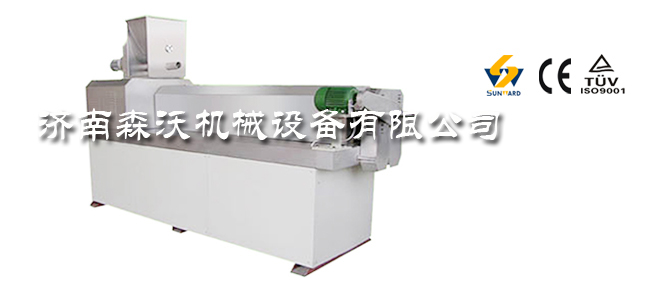

Jinan Sunward Machinery Co.,Ltd is a professional

Puffing equipment manufacturer. Our company could also supply many other equipments&parts including

puffed food processing line,

Ornamental fish feed processing line, textured soy protein processing

line, pet food processing line, floating fish feed processing line,

puffed feed processing line, nutritional rice processing line, corn

flakes processing line, Denatured starch processing line, core filling

food processing line, puffed leisure food processing line, Fried puffed

food processing line, Kurkure food processing line, breakfast cereal

processing line, puffed nutritional powder processing line, bread crumbs

processing line and so on.

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com